Gas and Watertight

Gas-tight covers and frames are often used to prevent odours from emitting from the services below. However, gas-tight covers are also water tight covers and can prevent water ingress into the services also.

There are a number of international standards relating to Access Covers… and whilst most of the world looks to the European Standard EN124, it is the Australian Standard, AS3996 which provides the industry and manufacturers a method of testing covers for gas-tightness and water-tightness. AS3996 was updated in 2019 and continues to lead the way globally for in-depth testing methodology for access covers.

Mascot Engineering have been manufacturing gas and airtight covers since the 1970’s. Our first significant project was for the NSW Parliament House, which also included our largest multipart cover assembly to date… a 100 part multipart.

Given the design of our gastight and watertight covers and frames are similar through the load ratings and sizes, we don’t do third party accredited tests for every cover we manufacture, instead choose specific products to ensure our methodology of design and the parameters we work to in manufacture and machining are correct.

AS3996:2019

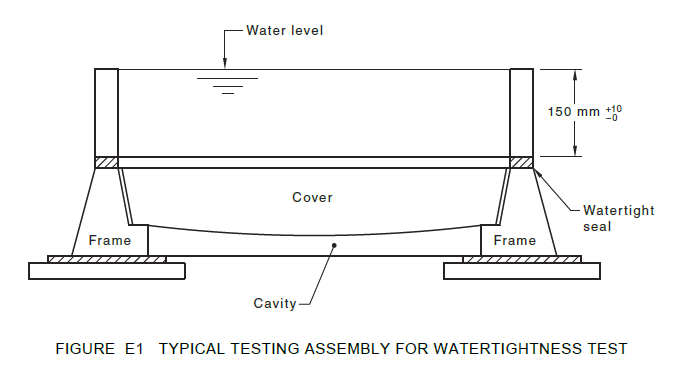

Appendix E – Method of testing covers for watertightness

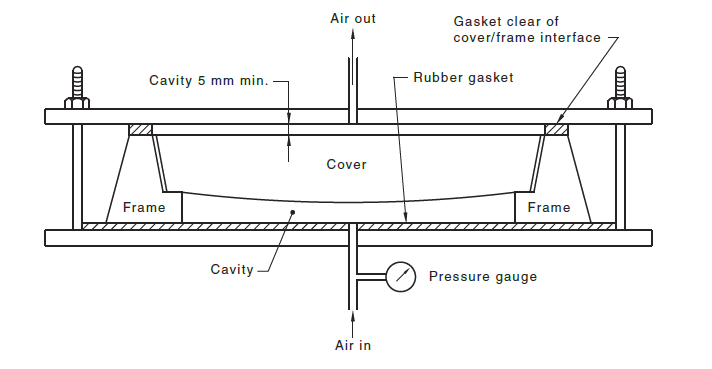

Appendix F – Method of testing covers for gas-tightness

Figure F1 Typical testing assembly for gas-tightness test

Contact our technical team on 02 9828 2600 for more information.

As with our installation and maintenance instructions and details, these tests also require the use of a sealant between the cover and the frame. Mascot Engineering use and recommend Manhole Cover Sealing Grease manufactured by Denso.

We stock and supply the cover sealing grease in 4kg tins. Details can be found here.