Technodrain

Mascot Engineering is proud to bring a world leading linear drainage product from Europe to Australia.

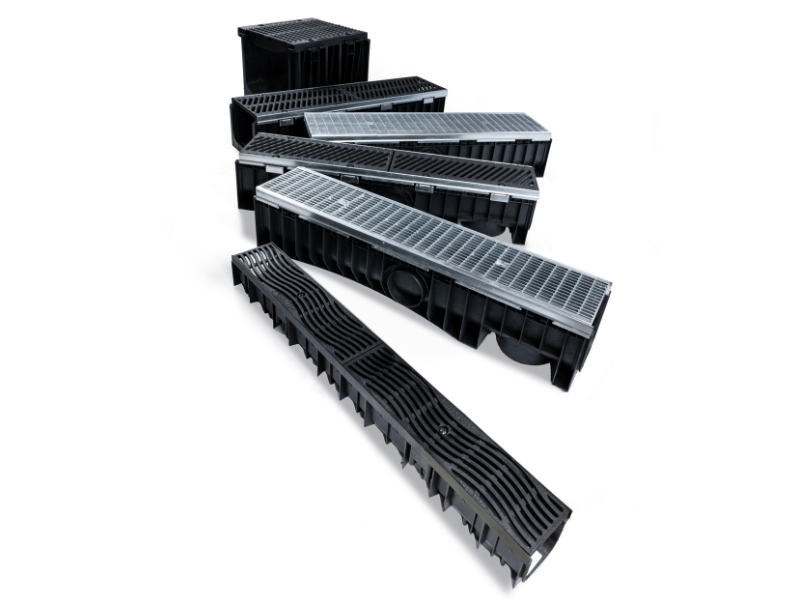

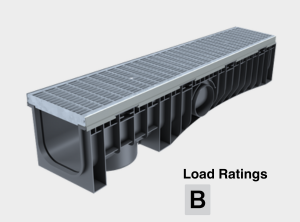

Innovative and easy to install linear drainage solutions from Italy. Technodrain is a lightweight, cost-effective, 100% recycled HDPE (High Density Polyethylene) channel paired with a range of sophisticated and compliant grates available in several widths and designs in Class B, D, E and Class G.

View the Technodrain brochure here.

Manufacturing – Technodrain & Mascot Engineering

Since 1978, Technodrain’s ISO9001 certified manufacturing facility (Asoplast) has been located just outside of the historical port city of Ancona in central Italy.

Their passion and dedication for manufacturing is evident in their large modern facility capable of producing 40,000kg of plastic material per day. Mascot Engineering share this passion for manufacturing and producing world leading products which makes Technodrain the perfect addition to the Mascot range of products.

Committed to sustainable and responsible manufacturing and a history of complex plastic moulding for automotive, household appliances and other industries, Technodrain was developed in 2004 in response to the markets demand for a high quality, strong, stylish and high performing drainage solution.

We’ve learnt a few things about drainage channels over the years and the Mascot Engineering team have carefully handpicked the range from Technodrain that we offer in Australia and New Zealand. We are aware that there are a number of similar products available, however the Wavedrain, Evomax and Magnum variants we’ve selected are best suited to the harsh Australian environment whilst offering a real benefit and difference to products currently in the market.

100% Recycled Materials

Sourced from industrial scraps and products at the end of their operational life, the Technodrain Channel body is crafted from 100% recycled high-density polyethylene (HDPE).

The raw recycled resources undergo a stringent procedure to ensure quality. The HDPE is meticulously controlled, mixed, and melted down to small pellets, ensuring consistency and purity in the materials. During this process, UV filters are added to enhance the finished products resistance to sunlight and environmental factors to extend its lifespan in demanding conditions.

Renowned for its durability, chemical resistance and long lasting properties, HDPE is the ideal choice for manufacturing high-performance drainage systems. The use of recycled HDPE with added UV protection ensures the product not only meets industry standards for functionality and durability but also minimises impact on the environment. Repurposing scrap materials significantly reduces waste and assists in conserving valuable resources.

Sustainability & Responsible Manufacturing

By turning industrial waste and everyday items into valuable resources, Technodrain contributes to a circular economy. The Technodrain Channel stands as proof that eco-friendly products can deliver the same, if not better, performance than traditional options. Mascot Engineering share this same commitment to manufacturing and we’re proud to play a part in building a cleaner, greener future where technology and sustainability work hand-in-hand.

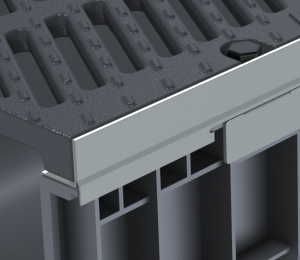

Protective Edges

Products subject to the heavy loads found in commercial, industrial and infrastructure projects need to be designed and constructed to suit. The Evomax and Magnum range from Technodrain are fitted with a protective edge frame to the top of the HDPE channel as standard. This innovative defensive edge rail is either galvanised steel (GMS) or ductile iron acting as a reinforcement ensuring the channel remains whole once installed.

Pedestrian Friendly – 10mm Heelproof (HP10)

Designing for the urban environment and future use is top of mind here at Mascot Engineering and the Technodrain grating range in Class B and Class D are all pedestrian friendly with grating gaps of no more than 10mm.

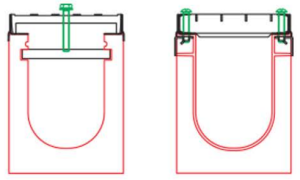

Boltdown as standard – Security

All Technodrain products come with a boltdown function. Not only does this keep the grate securely in place, it deters unauthorised removal and access. The boltdown system varies between the styles of grating and width of channels, more information can be found on the product specification sheets.

Non-Rocking Grating

To prevent grates rocking, the protective edge frame fitted to the Technodrain Evomax and Magnum range provide a level ‘seat’ surface that when paired with the boltdown facility reduces the chance of grates rocking whilst subject to traffic.

Modular Assembly

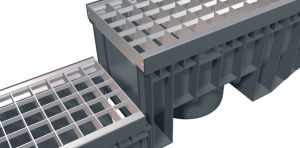

Technodrain is fitted with a tongue and groove end allowing for easy and simple joining of channels to create the length you need without fussy fixings and fittings.

Pre-Assembled

Technodrain is supplied with the grate and boltdown facility ready mounted and assembled saving you time on site. This ensures all required components are included when the product arrives on site. The 300mm Magnum product is supplied complete in 500mm lengths whilst the WaveDrain and Evomax are supplied in 1m lengths.

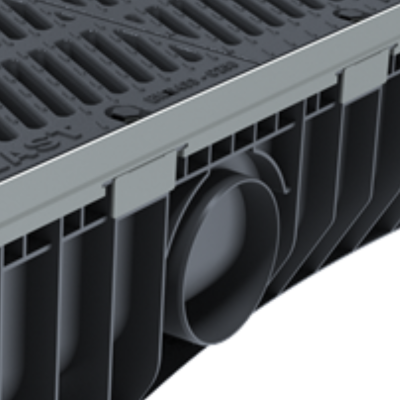

Hydraulic Flow & Knock-Outs

Paired with grating designed to maximise efficiency, to assist with high flow rates, the internal of all Technodrain channels are smooth and rounded (self cleaning) whilst each channel is fitted with pipe outlet points in both the sides and base.

Chemical Resistance

Technodrain’s high performance HDPE material is resistant to many checmical substances, the most common are found below;

Resistant to:

Hydrochloric Acid

Sulfuric Acid

Petrol

Diesel

Mineral Oil

Acetic Acid

Sodium Chloride

Sodium Phosphate

Sodium Hydroxide

Ethylic Alcohol

Ammonia

Antifreeze Salts

In addition to the above, Technodrain channel is also resistant to soap solutions and industrial cleaning products. Please contact us if you wish to discuss your specific installation.

Technodrain Range

Compliance – Standards

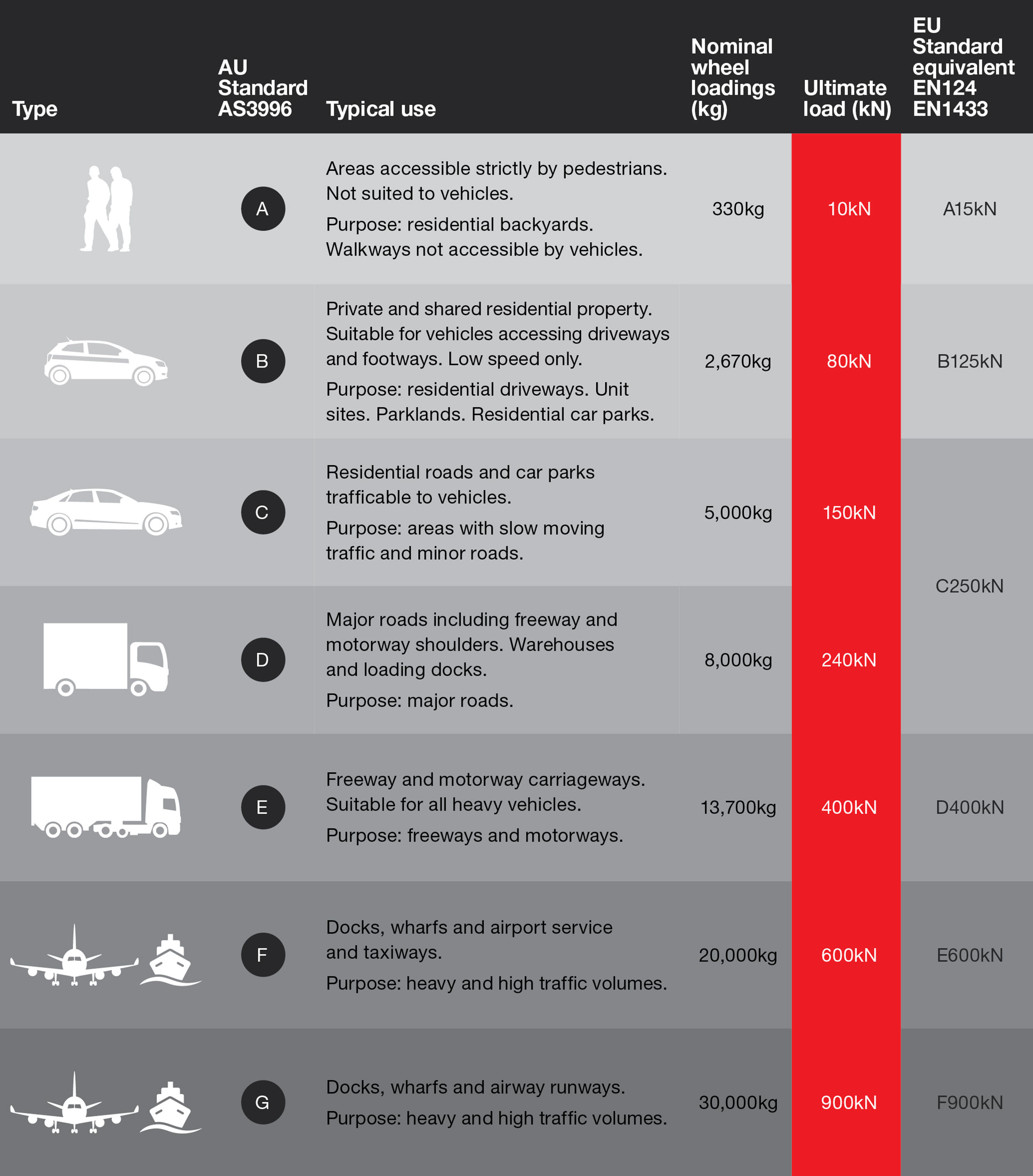

Standards vary around the world, however AS3996, EN1433 and EN124 are considered the leading standards internationally for access covers and grating.

Our extensive experience with AS3996 has allowed Mascot Engineering to supply projects around the world. In fact, we manufacture a range of EN124 (covers and grating) and EN1433 (trench grating) products that we supply globally.

As a European manufactured product, Technodrain is compliant to EN1433 – their version of our AS3996 which is the only internationally recognised standard written specifically for trench drains. EN1433 allows for more stringent testing of grates and channels allowing for the varying (often narrow) widths of channels.

The main differences between the EN and AS standards with the load ratings is the label. EN1433 goes from Class A to Class F and AS3996 goes from Class A to Class G. However, the range of testing in kilonewtons (kN) remains the same with EN Class F tested to 900kN… identical to Australian standard Class G which is tested to 900kN.

Visit our Load Ratings page under Technical Support to learn more about EN124, EN1433 and AS3996.